The Orange County Sanitation District (OCSD) has selected design consultants for a new $300 million temperature-phased anaerobic digestion (TPAD) facility at its Plant No. 2 in Huntington Beach.

Brown and Caldwell and Black & Veatch will work together to deliver professional design services, Brown and Caldwell said in a statement on Sept. 22.

After the design phase concludes by summer 2024, construction and commissioning of the TPAD facility is expected to start in 2025 and be complete by 2030.

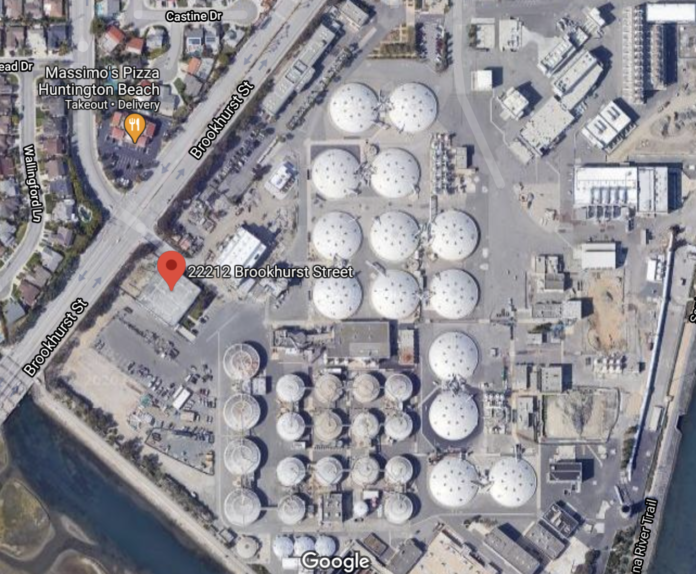

The 144-million gallons per day (MGD) capacity rated Plant No. 2 consists of 18 digesters built from 1959 through 1979. Due to their age, the digesters require significant rehabilitation to ensure protection against seismic hazards, comply with code, and be resilient to sea-level rise, as outlined in a 2015 structural/seismic hazard evaluation study by OCSD advising it to be more cost-effective to build new digesters than rehabilitate the existing.

Subsequently, OCSD’s 2017 Biosolids Master Plan (BMP) was developed to evaluate future biosolids management options and recommended capital improvement projects to upgrade solids handling facilities at the plant.

The new Class A TPAD facility is the largest of several projects resulting from the BMP and will be capable of processing all wastewater solids generated from Plant No. 2 until 2045.

The Class A TPAD system involves high temperature thermophilic anaerobic digestion at 131 degrees Fahrenheit followed by a 24-hour holding period in the batch tanks, sludge cooling, and mesophilic anaerobic digestion at 98 degrees Fahrenheit. The process provides greater solids process capacity and higher-quality Class A biosolids, and the TPAD system allows OCSD to mitigate the seismic risk while maximizing the use of their existing digesters.

“This important project supports OCSD’s commitment to providing a reliable service to our ratepayers, expanding resource recovery, and prolonging the life of our assets or replacing them with improved technology and innovative solutions,” said OCSD Director of Engineering Kathy Millea.

The project involves the construction of six new thermophilic digesters and six new Class A batch tanks at Plant No. 2, allowing the facility to generate Class A biosolids that meet U.S. EPA guidelines for land applications, including fertilizer on farms, vegetable gardens, and for residential use as compost or fertilizer. Digested sludge from the thermophilic digesters or Class A batch tanks will then be cooled and pumped to the existing mesophilic digesters before dewatering. In the event of a failure of the existing mesophilic digesters (e.g., seismic activity, structural failure), the new thermophilic digesters will be capable of processing all of the plant’s solids, thus mitigating seismic and operational risks with the existing digesters.

The project will offer operational flexibility to feed the existing mesophilic digesters while future projects replace and demolish other mesophilic digesters as identified in the BMP. The project also includes updating the master plan for the ultimate replacement of the existing digester complex.

Brown and Caldwell, in association with Black & Veatch, will develop and provide OCSD with a preliminary and final design for the new TPAD facility at Plant No.2. The final design will include configuration of the designated facilities, facility parameters, operation and maintenance information, and calculations required for construction.

“Our highly qualified team is thrilled to have been chosen for this project which represents a unique opportunity for OCSD to implement a next-generation biosolids facility in sync with its long-term goals,” said Brown and Caldwell Principal-in-Charge Dan Bunce.